We bring precision manufacturing expertise to some of the world’s most ambitious scientific projects, combining master craftsmanship with cutting-edge innovation.

Advancing Fusion Energy

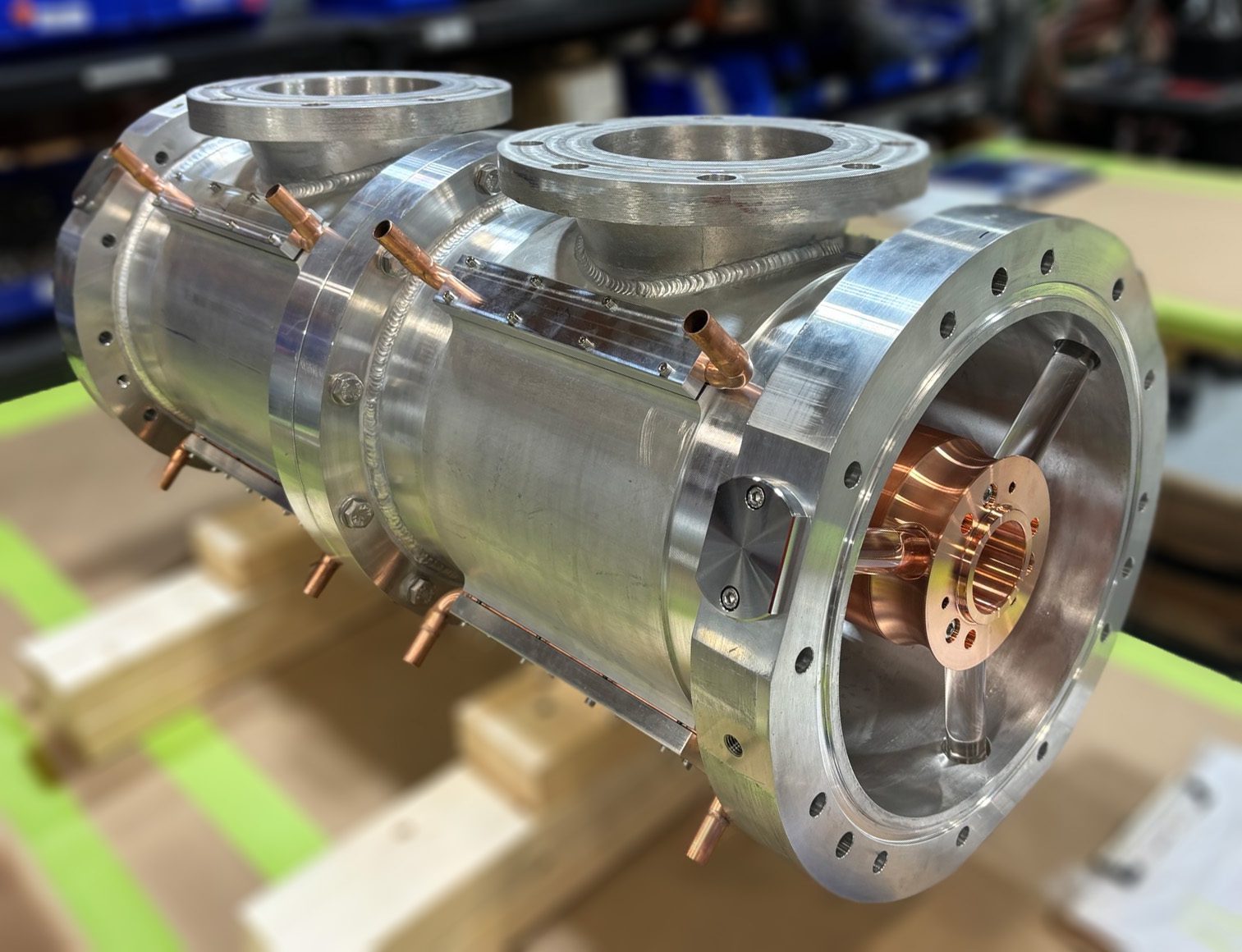

We’re proud to be part of the global effort to realize fusion energy’s potential. Working alongside the Department of Energy, national laboratories and research institutions, our team crafts critical passive RF components that help make fusion science possible.

Our specialized manufacturing capabilities support key components for fusion energy work, including critical systems that require the highest levels of precision and reliability. From plasma containment systems to specialized research equipment, we deliver passive RF components that meet the exacting standards of the fusion research community. Our engineering team brings the necessary expertise and collaborative mindset needed to work closely with your design team to help deliver components that can be manufactured cost-effectively, while optimizing overall RF system design.

Our work spans both domestic and international projects, where our expertise in specialized welding and high-precision manufacturing has made us a trusted fusion research partner.

The Art of Precision Welding

Dielectric is home to a team of master welders. Each welder brings 30-40 years of hands-on experience to the project at hand. These practitioners have perfected their craft through decades of working with the most demanding materials and specifications. They specialize in GTAW (TIG and MIG) processes for aluminum and stainless steel. Their expertise extends to brass and copper welding, where they’ve completed miles of precision work across various industries. Each is also certified in rigorous Welding Procedure Specification (WPS) standards.

Dielectric’s welding expertise encompasses the full range of precision requirements for scientific applications. Each project benefits from comprehensive quality assurance, along with our team’s deep understanding of specialized materials, high power RF characteristics, and complex geometries.

Beyond the Laboratory

In aerospace and defense, we manufacture mission-critical components that demand the highest levels of precision and reliability.

As an approved supplier for scientific communities, we understand the unique requirements of research and development projects. Our experience includes custom fabrication for specialized research equipment and complex experimental apparatus, always meeting the rigorous standards demanded by scientific applications.

Whether it’s passive RF components for advanced scientific instruments, aerospace systems, or next-generation energy research, our commitment to precision and quality remains unwavering. Each project benefits from our decades of experience and our culture of continuous innovation.

Gas barrier prototype produced for US ITER

Recent Affiliations

Dielectric boasts a long history of supporting leading-edge energy technologies. Dating back to as far as the 1960s and 1970s, Dielectric has worked with the Stanford University SLAC National Accelerator Laboratory, Los Alamos Labs, Sandia National Labs and Lawrence Livermore National Labs.

More recently, with resurgence of int erest in fusion technology, Dielectric has supported the innovation efforts of:

- Lockheed Martin

- DOE – Oak Ridge National Lab

- University-affiliated laboratories across the world

READY TO EXPLORE THE POSSIBILITIES?

Whether you’re pushing the boundaries of fusion science, developing aerospace innovations, or pioneering new research frontiers, we’re here to help bring your vision to life.